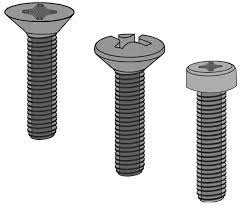

Introduction: cross recessed machine screw are a fundamental component in various industries, from construction to manufacturing. Their unique design and versatility make them a go-to fastener for countless applications. In this article, we’ll explore the ins and outs of cross recessed machine screws, providing you with an in-depth understanding of their uses, advantages, and common questions.

Headings with FAQ:

FAQ 1: What Are Cross Recessed Machine Screws? Cross recessed machine screws are threaded fasteners with a specialized recess on the head. This recess typically has a cross-shaped pattern, also known as a Phillips drive. The design of the head allows for easy engagement with a screwdriver or power tool.

FAQ 2: What Makes Cross Recessed Machine Screws Different from Other Screws? Cross recessed machine screws stand out due to their distinct head design. They are especially suitable for applications where you need a screw that is easy to tighten and loosen, even in challenging conditions. The cross pattern provides a secure grip and reduces the likelihood of cam-out (slipping) compared to other screw types.

FAQ 3: Where Are Cross Recessed Machine Screws Used? These screws are widely used in various industries, including electronics, automotive, furniture, and machinery. They are a common choice for assembling electrical components, household appliances, and industrial machinery. Additionally, they are frequently used in construction, particularly in woodwork and metalwork.

FAQ 4: What Are the Advantages of Using Cross Recessed Machine Screws?

- Efficiency: Cross recessed machine screws can be quickly driven in and out with compatible tools, saving time and labor.

- Reduced Cam-Out: The design of the cross recessed head reduces the risk of the screwdriver or bit slipping out, preventing damage to the screw or workpiece.

- Secure Fastening: The cross pattern provides excellent grip and torque transfer, ensuring a tight and reliable connection.

FAQ 5: What Types of Materials are Cross Recessed Machine Screws Made From? These screws can be found in a wide range of materials, including stainless steel, brass, and various types of steel. The choice of material depends on the specific application and the desired level of corrosion resistance.

FAQ 6: Are There Different Sizes and Lengths Available? Yes, cross recessed machine screws come in various sizes and lengths to accommodate different applications. The size and length you need depend on the thickness of the materials you’re fastening together and the required load-bearing capacity.

FAQ 7: How Do I Choose the Right Cross Recessed Machine Screw for My Project? Selecting the appropriate screw involves considering factors such as material compatibility, size, length, and the specific requirements of your project. It’s advisable to consult with a hardware expert or refer to the manufacturer’s recommendations.

FAQ 8: Can I Use a Regular Screwdriver with Cross Recessed Machine Screws? You can use a regular screwdriver with these screws, but it’s recommended to use a Phillips screwdriver or a power tool with a Phillips bit for optimal results. The Phillips design is specifically engineered to fit the cross-shaped pattern.

FAQ 9: What Are Some Tips for Properly Installing Cross Recessed Machine Screws?

- Ensure the screwdriver or bit fits securely into the recess.

- Apply even pressure while driving the screw to prevent damage.

- Use the appropriate size and length of the screw for your project.

- Avoid over-tightening, as it can lead to thread damage.

Conclusion: Cross recessed machine screws are an essential component for a wide range of applications. Their unique design and advantages make them a top choice for professionals in various industries. By understanding their features and how to use them effectively, you can ensure secure and efficient fastening in your projects.

FAQ 1: What Are Cross Recessed Machine Screws?

Cross recessed machine screws are threaded fasteners with a specialized recess on the head. This recess typically has a cross-shaped pattern, also known as a Phillips drive. The design of the head allows for easy engagement with a screwdriver or power tool.

FAQ 2: What Makes Cross Recessed Machine Screws Different from Other Screws?

Cross recessed machine screws stand out due to their distinct head design. They are especially suitable for applications where you need a screw that is easy to tighten and loosen, even in challenging conditions. The cross pattern provides a secure grip and reduces the likelihood of cam-out (slipping) compared to other screw types.

FAQ 3: Where Are Cross Recessed Machine Screws Used?

These screws are widely used in various industries, including electronics, automotive, furniture, and machinery. They are a common choice for assembling electrical components, household appliances, and industrial machinery. Additionally, they are frequently used in construction, particularly in woodwork and metalwork.

FAQ 4: What Are the Advantages of Using Cross Recessed Machine Screws?

- Efficiency: Cross recessed machine screws can be quickly driven in and out with compatible tools, saving time and labor.

- Reduced Cam-Out: The design of the cross recessed head reduces the risk of the screwdriver or bit slipping out, preventing damage to the screw or workpiece.

- Secure Fastening: The cross pattern provides excellent grip and torque transfer, ensuring a tight and reliable connection.

FAQ 5: What Types of Materials are Cross Recessed Machine Screws Made From?

These screws can be found in a wide range of materials, including stainless steel, brass, and various types of steel. The choice of material depends on the specific application and the desired level of corrosion resistance.

FAQ 6: Are There Different Sizes and Lengths Available?

Yes, cross recessed machine screws come in various sizes and lengths to accommodate different applications. The size and length you need depend on the thickness of the materials you’re fastening together and the required load-bearing capacity.

FAQ 7: How Do I Choose the Right Cross Recessed Machine Screw for My Project?

Selecting the appropriate screw involves considering factors such as material compatibility, size, length, and the specific requirements of your project. It’s advisable to consult with a hardware expert or refer to the manufacturer’s recommendations.

FAQ 8: Can I Use a Regular Screwdriver with Cross Recessed Machine Screws?

You can use a regular screwdriver with these screws, but it’s recommended to use a Phillips screwdriver or a power tool with a Phillips bit for optimal results. The Phillips design is specifically engineered to fit the cross-shaped pattern.

FAQ 9: What Are Some Tips for Properly Installing Cross Recessed Machine Screws?

- Ensure the screwdriver or bit fits securely into the recess.

- Apply even pressure while driving the screw to prevent damage.

- Use the appropriate size and length of the screw for your project.

- Avoid over-tightening, as it can lead to thread damage.

Conclusion:

Cross recessed machine screws are an essential component for a wide range of applications. Their unique design and advantages make them a top choice for professionals in various industries. By understanding their features and how to use them effectively, you can ensure secure and efficient fastening in your projects.